Mechanical Sealing System & Heat Shrink Sleeve for Infinity Closure

When working with fiber optics, the installation and maintenance of splice closures are important to ensure the integrity and performance of a network. These closures serve as protective enclosures for fiber optic splicing, safeguarding the delicate connections from environmental factors.

Yelco's Infinity Closure is a prominent solution in this field, offering innovative solutions for efficient and reliable fiber optic network installations. An essential specification that makes the Infinity Closure stand out is the available option to install it either with mechanical or with thermal sealing systems. Both options play a crucial role in assuring the protection of the closure.

What are Heat Shrink Sleeves?

Heat shrink sleeves are the most common sealing system for the cables that are introduced in fiber optics splice closures. These sleeves are typically made of materials like polyolefin.

When heated, these sleeves tightly constrict around the cables providing an airtight and watertight seal.

Benefits of Heat Shrink Sealing Systems

The incorporation of heat shrink sleeves in fiber optic splice closures offers several benefits:

- Reliable Sealing: Heat shrink sleeves ensure reliable sealing, preventing moisture ingress and protecting sensitive optical components from humidity and other environmental factors.

- Mechanical Protection: They act as a protective barrier, shielding cables and splices from physical damage, making them suitable for installations in harsh environments.

- Enhanced Performance: By maintaining stable environmental conditions, heat shrink sleeves contribute to the long-term performance and reliability of fiber optic networks.

- More economic: the heat shrink sleeves are less expensive than mechanical sealing systems.

Less positive aspects of using Heat Shrink Sealing Systems:

- Heat Shrink sleeves are non-reusable. If needed to remove the cable, a new heat shrink sleeve needs to be applied.

- It requires the use of heat sources to heat shrink the sleeves.

- Either it is used a torch, which can be dangerous and can burn and damage the cables and the closure.

- If it is used an electrical heat gun, which requires electrical energy.

- To avoid damages, it requires a skilled technician.

- It takes more time to install properly than mechanical seals.

Thermal sleeves are cheaper and more standard. However, once sealed, they are not reusable. The application of heat, if not careful, can damage the cable and the joint. The use of heat sources can be dangerous in environments with explosive gases (this is called ATEX - explosive atmosphere research).

The use of sleeves requires knowledgeable technicians. It requires more time, more skill. Where labour is cheap, it pays off in relation to the material increase of other sealings.

What are Mechanical Sealing Systems?

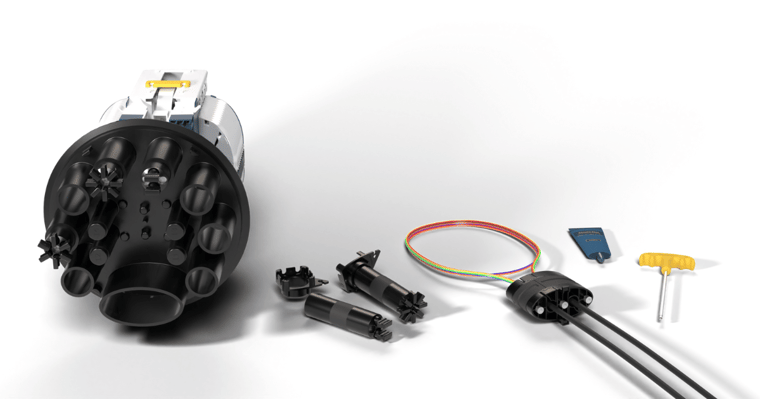

Mechanical sealing systems, in the context of fiber optic splice closures, refer to a system that seals the cable entry ports by mechanical means. No need to apply heat or any other chemical sealant to provide sealing of the closure.

Benefits of Mechanical Sealing Systems

The utilization of mechanical sealing system in fiber optic splice closures offers several advantages:

- Reliable Sealing: Mechanical Sealing Systems ensure reliable sealing, preventing moisture ingress and protecting sensitive optical components from humidity and other environmental factors.

- Mechanical Protection: They act as a protective barrier, shielding cables and splices from physical damage, making them suitable for installations in harsh environments.

- Enhanced Performance: By maintaining stable environmental conditions, heat shrink sleeves contribute to the long-term performance and reliability of fiber optic networks.

- Adverse Environments: they can be used in areas where using sources of heat can be dangerous, like places with explosive or flammable gas.

- Easy Application: Can be applied by less skilled personnel because it is easier to install and don’t require the use of dangerous tools like torches.

- Reusable: It can be reused as many times as needed.

Less positive aspects of using Heat Shrink Sealing Systems:

- Mechanical sealing systems are more expensive, in terms of material cost.

- The technician must confirm that the system is well installed so to prevent water ingression in the closure.

These can be used in environments with risk atmospheres, as there is no need to apply heat, such as in environments where there may be combustible gases.

These devices can be used by less experienced technicians. They’re quicker to install, easier. Good for use where labor is expensive compared to the material.

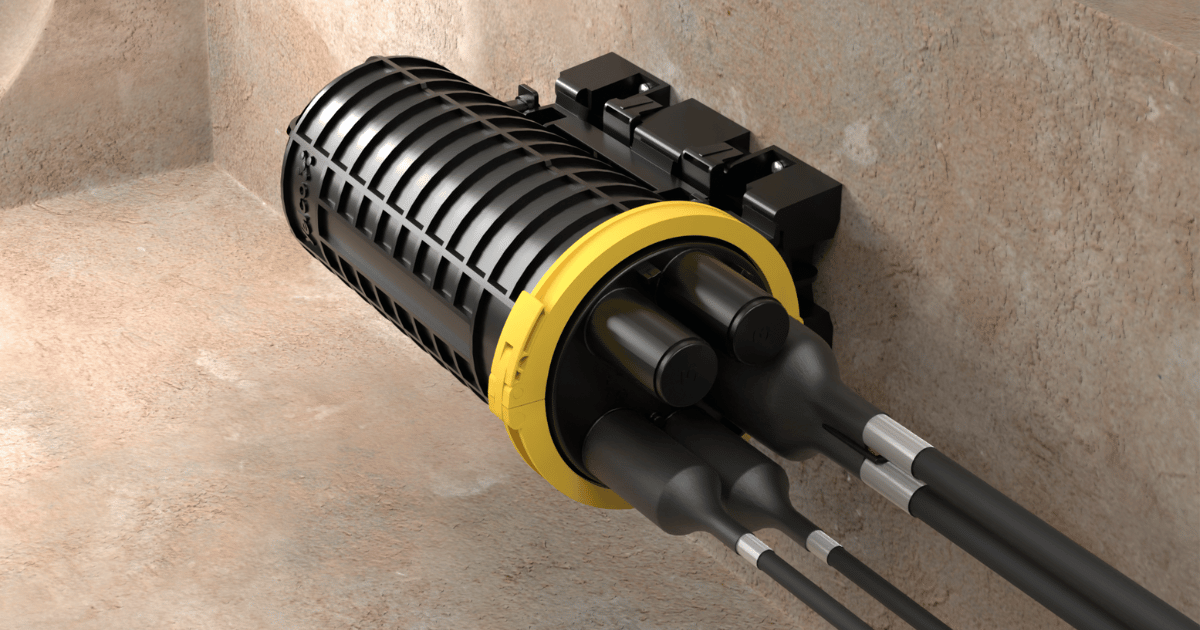

Using these Systems in Yelco's Infinity Closure

Yelco's Infinity Splice Closure is designed to provide maximum protection and flexibility for fiber optic network installations. Both options can work greatly in the mission of protecting the cable connections and guaranteeing their long-term performance and protection.

With either the benefits of mechanical sealing system and heat shrink sleeves, Yelco's Infinity Closure offers a comprehensive solution for efficient and dependable fiber optic splice closure installations. These options of security, environmental resilience, and cable protection ensure that your network remains reliable, even in the most challenging conditions.

The installation of fiber optic splice closures is a critical aspect of network planning and design, and the choice of components like mechanical sealing system or heat shrink sleeves can significantly impact network performance and longevity. Yelco's Infinity Closure allows the use of both these components to provide a robust and dependable options for modern fiber optic networks.

Learn about the Infinity Closure, its Mechanical Sealing System and Heat Shrink Sleeve here.