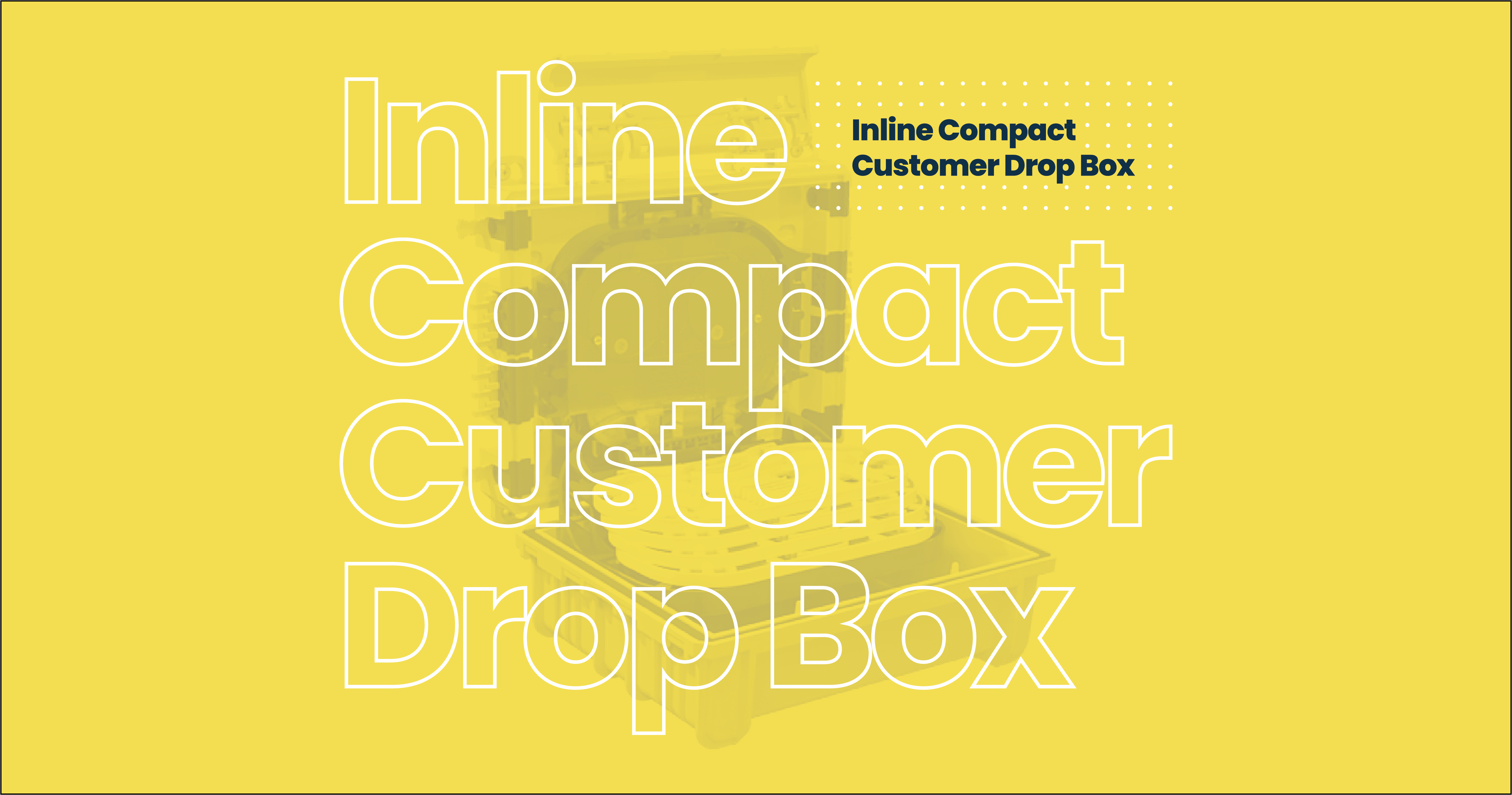

Next Generation of the Fiber Termination Box: Meet the Inline Compact Customer Drop Box

With the continuous growth of fiber optic networks, managing optical networks is becoming more and more challenging resulting in the need for new solutions and upgrades. This new generation of termination boxes, the Inline Compact Customer Drop Box, has become a crucial component to help manage fiber optics in the most seamless way, considering that the installation of these boxes has the least possible impact on the environment, while also reducing operational cost and increasing the flexibility of its management.

What is the Inline Compact Customer Drop Box

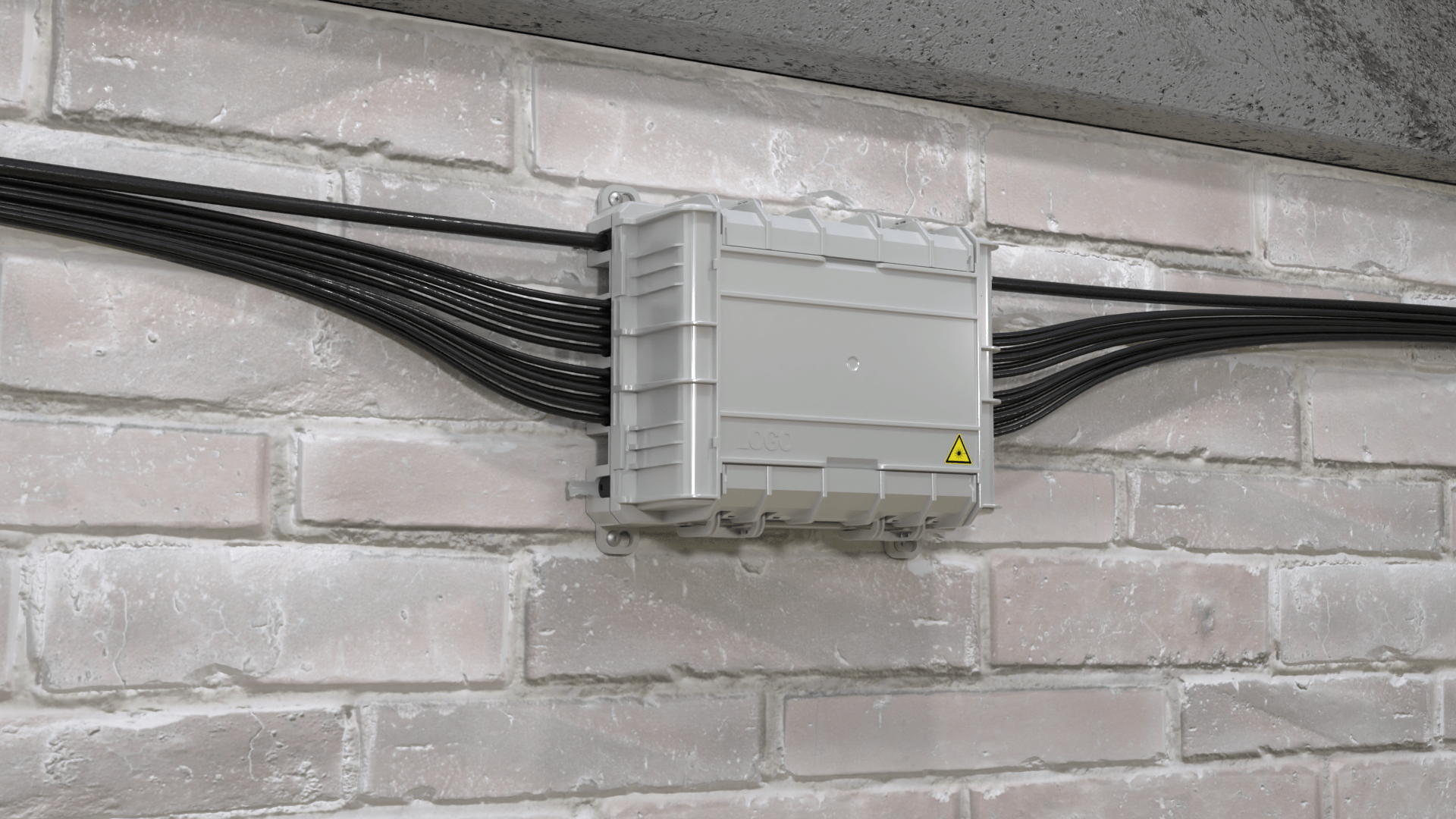

The Inline Compact Customer Drop Box is a type of FO termination box that was developed to be installed in building façades, especially in older neighborhoods, where FO networks have to reach residences whilst creating the least possible impact on the environment and infrastructure.

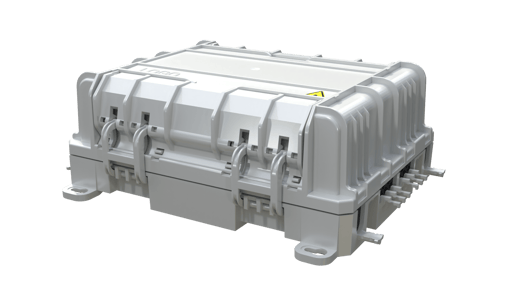

This termination box can connect up to 24 drop cables to connect 24 possible customers, with the ability to make mid-span in the distribution cable, being an ideal solution to make a line of several buildings with just one feeder cable. The box is equipped with a bottom tray that will allow the organization of the feeder cable tubes and the execution of 12 fiber optic splices. Attached to this bottom tray, there is a pivoting fiber routing system that holds 4 trays, being that each tray can hold up to 12 fiber optic splices and one PLC splitter (4 to 7 mm PLC module), summing a total of 48 fiber optic splices and 4 PLC splitters.

The big challenge here was to have all these capabilities within the limitation of the external overall dimensions of the box: 205 x 155 x 80 mm (L x W x D)

What’s the main difference from a regular fiber termination box?

The Inline Compact Customer Drop Box, is not a regular fiber termination box. It became reality as a response to a challenge posed by a Telecom Operator, with the problem to place termination boxes in city centers, where the buildings are older and lack the infrastructure for networks, which is a problem shared by telecom operators in general.

This new product was developed under the compliance of several basic premises:

- Separation between feeder cable splices and drop cable splices: 12 fo splices for feeder cable, with the ability to physically separate the fusion splices from the drop cable fusion splices, helping prevent the installer from using the wrong fibers;

- No cable slacks: Inline box which allows the installation without the need of cable slacks, as the cable can enter and exit directly without the need to make cable slacks, creating less impact in the façades of the buildings;

- Compact: Small form factor termination box with reduced dimensions to create less impact;

- Customer connection capacity: 24 drop cables to be organized in 4 splice trays, which allows a total of 48 fusion splices;

- Integrated with the installation environment: Injected in Grey color (RAL 7035) so it can be easily concealed in the environment it is installed.

Apart from all that was mentioned previously, Yelco developed this product to also be installed in underground infrastructures. With the addition of extra clamps, the box will acquire a higher IP index, which will allow it to be installed in manholes.

Learn more about the Inline Compact Customer Drop Box.

Want to know how to customize or create a tailor-made product for your network? Know more about Yelco.