3D Printer Types: What you Should go For

Either you’re looking to get a 3D Printer for yourself or to request for a 3D printing service, knowing what type of printer you’ll require for the specifications of your project is essential to get the desired outcome.

What is a 3D Printer?

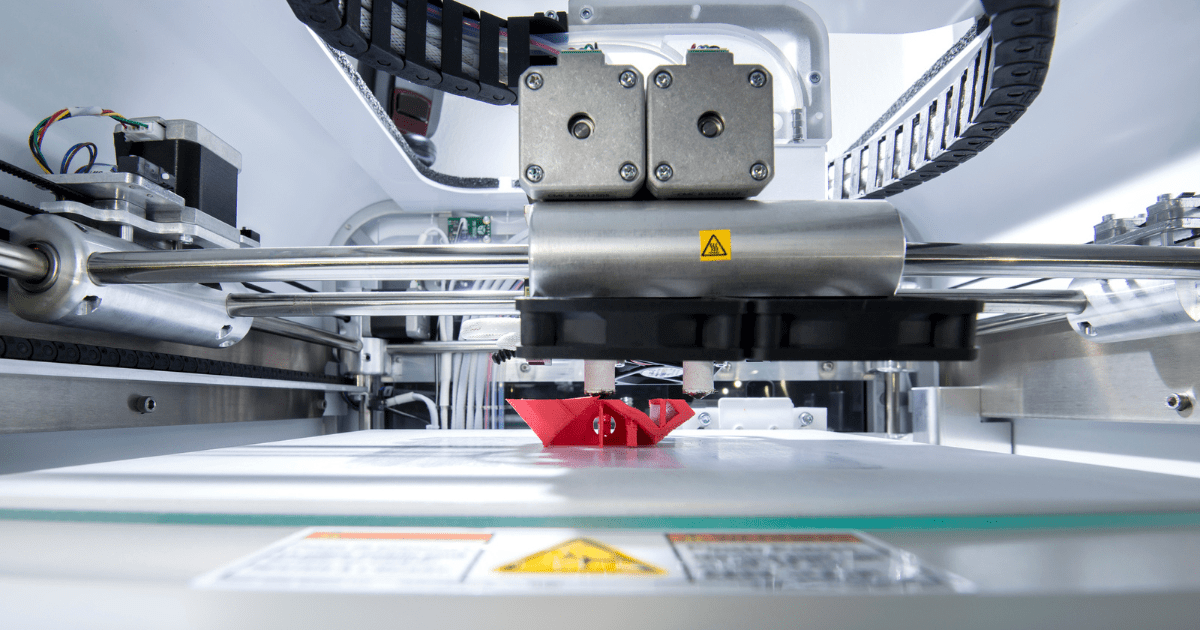

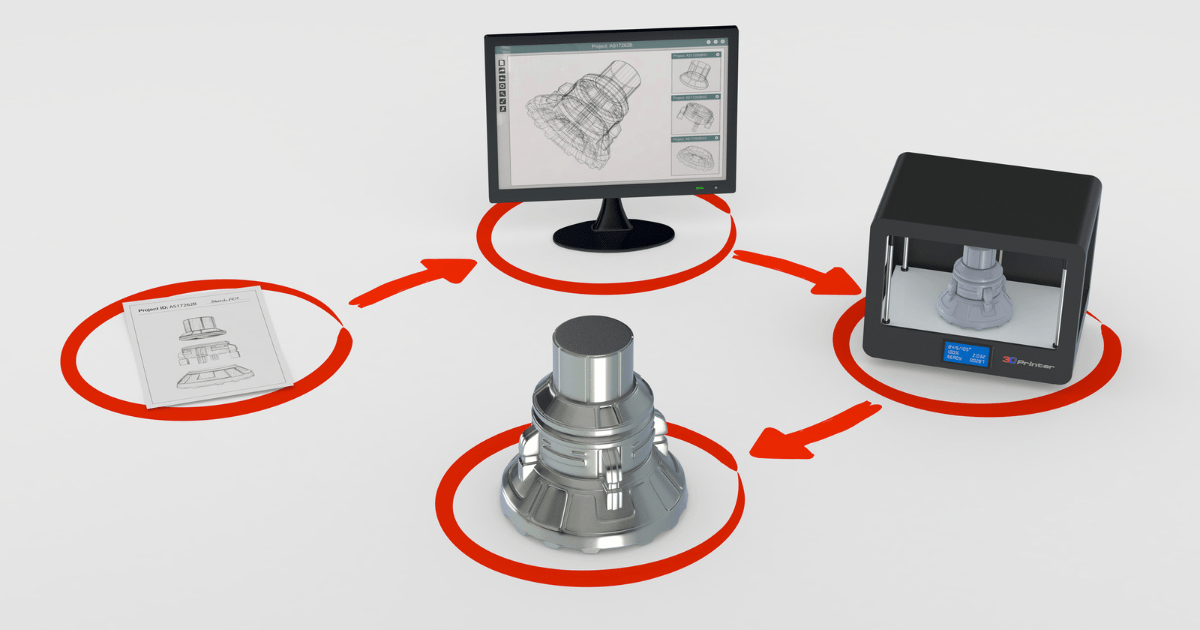

A 3D Printer is essentially an equipment for additive manufacturing processes. This form of technological printing manufactures tridimensional models, by layers, from 3D digital designs.

Through an STL file, transformed to a G-code that is read by the equipment, 3D printing allows to materialize design ideas into a quality prototype, an approximation to the real final product.

With these prototypes, you’re able to test your designs in a more sustainable way, without wasting resources on factory productions right away.

What Types of 3D Printers and Technologies exist?

There are many different types of 3D Printers that use different technologies. Some of these types are:

- FDM (Fused Deposition Modeling),

- SLA (Stereolithography),

- SLS (Selective Laser Sintering),

- DLP (Digital Light Process),

- MJF (Multi Jet Fusion),

- DMLS (Direct Metal Laser Sintering) and

- EBM (Electron Beam Melting).

All these 3D Printers use different technologies and materials, with different specifications, abilities and costs. Characteristics that can make a huge difference when printing your model.

What are the Main Limitations of 3D Printing?

Even though 3D printers allow for more sustainable and resource-saving prototyping processes, they still have some limitations. Some of those are:

- It’s still an expensive technology. Through the years, 3D Printers have become more accessible, but they still require high investments to acquire. These allow for saving resources long term but need a big budget to begin with.

- Maintenance is also not cheap. This type of equipment needs regular maintenance, sometimes needing to exchange parts that are somewhat pricy. Not keeping up good maintenance practices can compromise the well-functioning of the 3D Printer.

- 3D Printing takes time. It’s not the fastest process, but it allows to save a lot of resources.

- It requires knowledge. Working with a 3D Printer is not something that can be done by anyone intuitively. In most cases, to best handle this type of equipment, it’s important to invest in training courses.

Overall, if you consider investing in a 3D Printer, keep in mind that it’s not an investment that will give you a financial return right away, but instead it makes up for its cost on a long-term period. If you’re thinking about purchasing a 3D Printing service, know that you won’t have the fastest response, but a quality and resource-saving one.

How to Choose a 3D Printer

As said at the beginning, choosing the right 3D Printer is essential to get the desired outcome for your project.

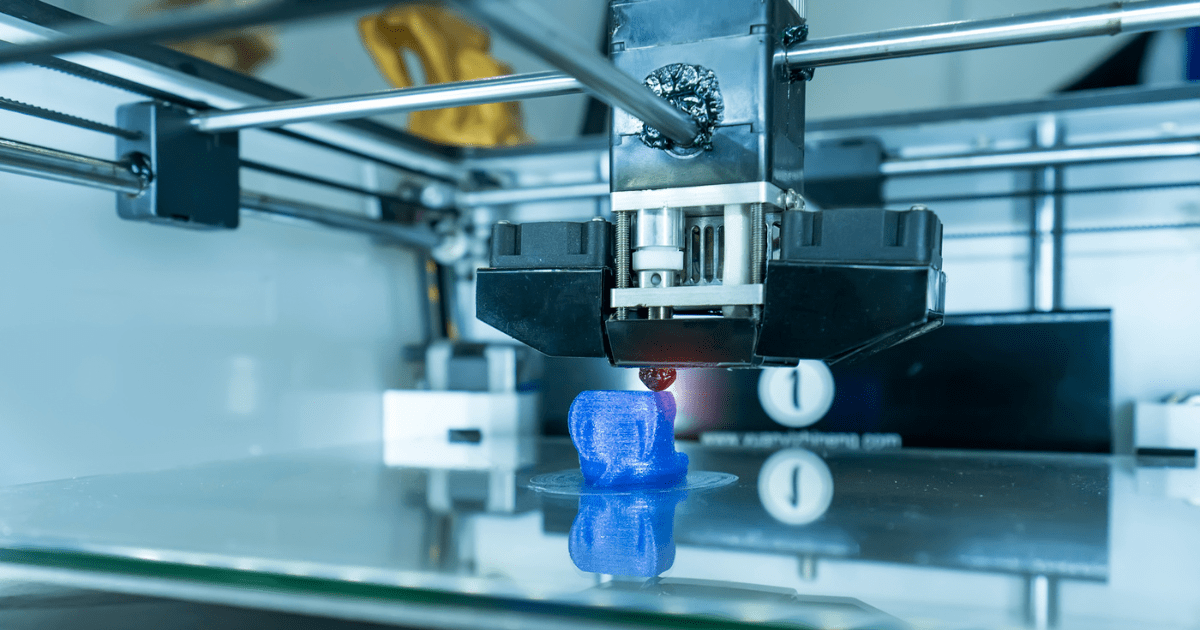

For example, if your desired outcome is a faster response with not the greatest precision, FDM is probably the best technology for you to go with. But if you’re looking for a more resistant and precise prototype, and don’t mind waiting a little longer, SLA can be a good fit.

Both productions can even be used as a final product themselves, but it’ll always depend on how resistant you want your model to be, how big, how precise, how fast you want to get it, how much money you want to spend, etc. These are all factors that you should consider and look into when searching for the right printer.

Every 3D Printer has its specifications, and some can be a greater fit for your project than others.

Where to print?

If you’re looking for a place to print your 3D designs, Yelco is the right place.

At Yelco, we provide both FDM and SLA printing services, depending on what your needs are.

Even though we work in the telecommunications field, we produce 3D projects for any customer that requires this service.