Co-Creation in Innovation Process: How this Model is Accelerating Telecom Products and Services Efficiency?

Keeping the R&D department continuously developing innovative products is a huge challenge. On top of that, in a technological area that is always in constant evolution. Companies and R&D departments follow the market, but how do you know what the right approach is when starting product development?

A product is created to satisfy customer needs and to solve a problem. So how to ensure that these premises are met and, at the same time, have a “fresh” approach to the topic and have new approaches to the product so that it is truly innovative and disruptive?

At Yelco Technologies, we believe that co-creation in innovation is the key to creating a meaningful product.

What is Co-creation in Innovation Process?

We see co-creation as a process of product innovation and development where we involve various stakeholders in the creation process. In addition to the R&D team, which is a natural actor in this process, we include other people from the company, from other areas, as well as external actors, whether customers, technicians or even people from other business areas.

The idea is to approach problems with a different perspective and thus obtain better products and improve innovation processes.

How is Co-Creation Done in the Development of a Product?

When starting the process of developing a product, as explained above, the challenge launched by the customer to solve a problem or need is considered, and baselines are defined in which all the development will take place.

This moment is crucial, because it is when all the important questions must be asked and all pertinent questions must be placed on the table, as these will influence the entire development from now on. It is at this moment that the co-creation process begins, because, although there is already a basic idea, we involve the client in an interactive process, from the first paper sketches or from the first 3D printed prototypes, to assess whether the idea of the R&D team and their idea coincide.

This involvement has proved to be extremely effective, as it is at this stage that ideas begin to take shape and are confirmed as good ideas, or are discarded, and a new creation process begins to materialize a new idea.

What are the benefits of this process?

In a B2B business model, such as is Yelco Technlogies’ business, where the number of customers is limited and the type of products is very specific, the co-creation in innovation process is almost mandatory, in order to obtain a successful product.

The benefits of adopting a co-creation process are numerous, of which we will list a few:

- Better products

A product is successful if it is made according to customer or market needs and solves a problem. For that, something new has to be created, because if it existed on the market, the problem would be already solved. And if you're going to create something new, then you're going to do something better.

- Creation of an economically viable product

By interacting with the various actors throughout the creation process, we will create an optimized product, a product that has been refined throughout the process, from which all non-essential or useless features have already been eliminated. In this way, a highly efficient, simple and inexpensive product will be created, which keeps the customer satisfied and solves the problem.

- Stakeholders become “owners” of the product

The involvement of several people in the process of creating a product is an inestimable value, as they increase the development team without including them in the pay roll.

Because they are involved in the process, they become “owners” of the product, assuming, in some way, the responsibility for the success of that product.

It increases customers' confidence and a sense of belonging, as they see their ideas applied and taken seriously.

- Emergence of “out of the box” ideas

There are no absurd ideas, but ideas. Sometimes the idea that seems to make the least sense is the one that will give rise to a disruptive and truly innovative product. Therefore, the participation of actors outside the business area can be beneficial and very important.

Examples of Co-Created Products at Yelco Technologies

Since 2014, Yelco Technologies has been developing custom-made products, and most of them were made in a co-creation process, both with customers and field technicians, as well as with company colleagues from other areas.

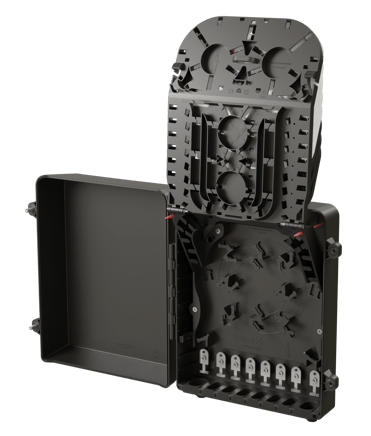

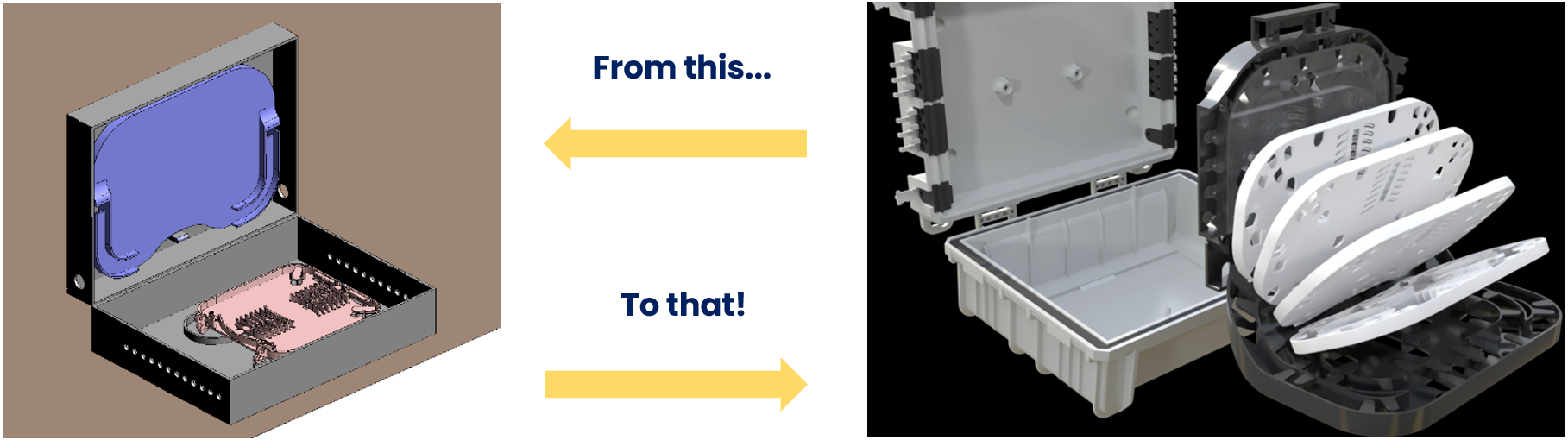

- Backpack Closure

In 2016, Yelco Technologies was challenged to find a product on the market capable of meeting several requirements, the main ones being:

- make physical separation of important optical fibers from customer drop fibers;

- have great fusion splice capability (more than 144 splices);

- be the same size as the existing termination box.

Based on these challenges, and through an interactive process of co-creation, the Backpack Closure emerged. A truly innovative and disruptive product, capable of fulfilling the proposed requirements and delivering even more features than those requested. This was only possible due to the involvement, in the process, of the customer, the R&D team and technicians specialized in optical fibers, who gave their very important contribution to the existence of this product.

The success was such that it originated a program to reduce operating costs inside the operator and has already been adopted by more operators.

|

Interior of the backpack closure. |

Backpack Closure with sliding system on the cover to install the termination box in front. |

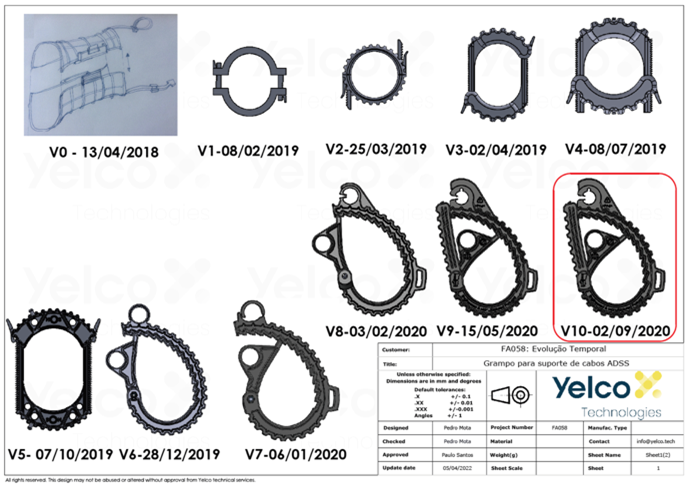

- Clamp for Securing Excess Slack

The clamp for securing excess slack is another example of a product made in a co-creation process, mainly with the end customer, who was part of the creative process, in the interaction with the R&D team in the development of the various versions, in-field testing of the 3D prototypes, until reaching the final product.

|

Evolution of the design of the clamp, from the concept to the final product. |

|

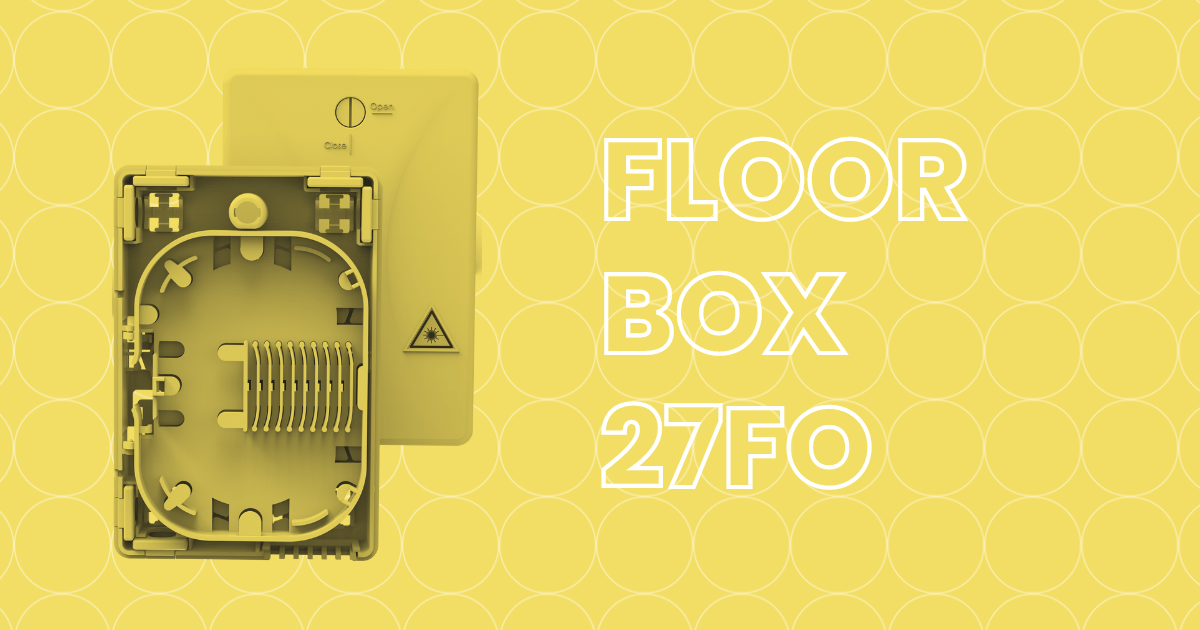

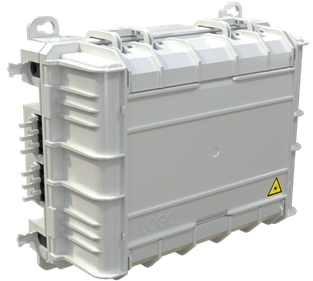

- Compact Inline Customer Drop Box

The latest example of co-creation at Yelco is the compact inline customer drop box. This was a challenge launched by an operator to develop a solution with very specific characteristics, but with a very important premise: the product had to be ready by the end of the year.

From the beginning, full interaction with the customer was requested, in which the customer participated in development meetings, validated the product concept through a 3D prototype, etc. Through this cooperation, it was possible to deliver the product that the customer asked for, solve his problem, and deliver it within the defined timeline.

From ideation to final product it took only 8 months! |

|